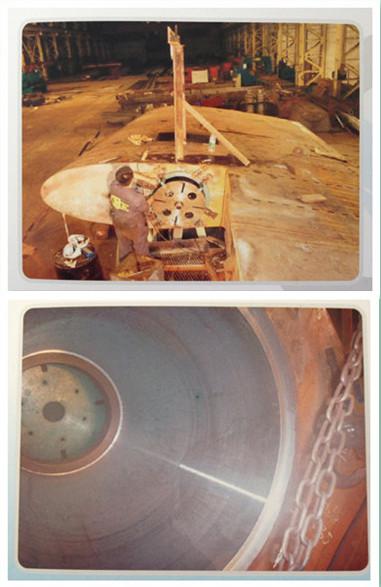

| Boring a rudder stock taper hole in totally 3 days.

Surface: Ra1.6

Hole size:Φ544.85mmXΦ602.85mmXΦ870mm(L)

Customer Located: Canada. |

Fit Tools onto the Flange |

Initial Machining |

Effect after machining |

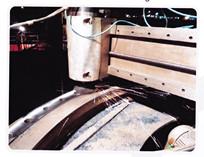

| | | Facing up pedestal flange for deck crane in totally 2days.

Surface:Ra1.6

Machining value: 3mm

Flange size:Φ4860mm

Customer located: Greece |

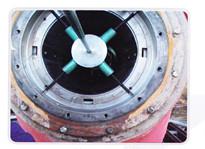

Polishing a crankpin in 3 hours

Model: MAN B&W 7S60MC

Surface: Ra0.4

Customer Located: Germany

|  |

| Polishing crankshaft | After Polishing |

Grinding engine frame for 7 cylinders in 2 days.

Surface:Ra0.4

Size grinded off: 0.4mm

Customer Located: Denmark

|  |  |

| | Polishing Process | Final Inspection |

|  |

Fitting Tools | Boring Process |

At the request of shipyard,we design the in-situ machining tools for the large part of FPSO Item. High-quality completed the inner hole three taper, two right angles and R’s perfect connection.

Get the height approval of the shipyard and owner.

Owner: SBM Company

Repair on engine frame

|  |  |

| Rebuild cooling hole on damaged engine frame | Boring new hole to fit new bush | Boring finished |